Products

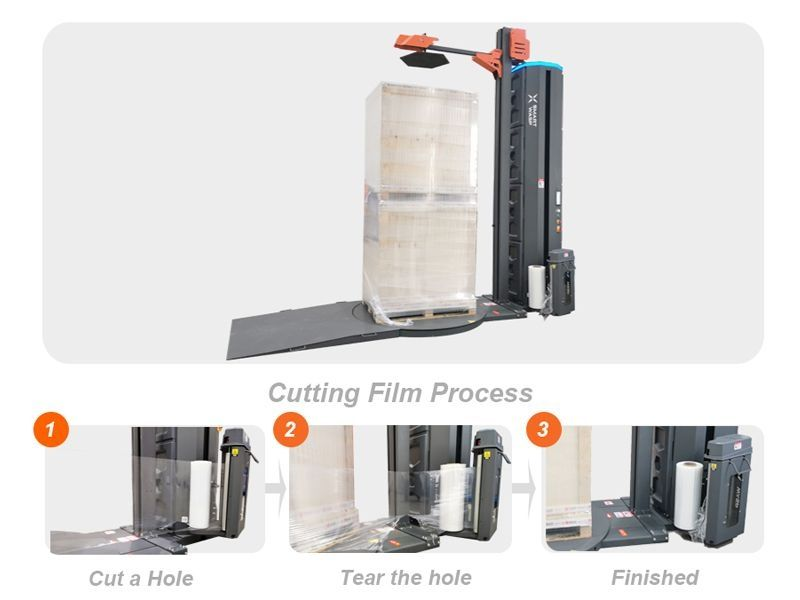

Automatic Cutting Film

After finishing wrapping the pallet, our pallet stretch wrapper will cut the film automatically. There is no need for workers to cut the film with tools, which is very helpful for users.

Multi-layer Function

This function can set different wrapping circles and wrapping forces at any height that you want. And the maximum Stretch Pallet Wrapping Machine can set is 9 layers for the pallet. Normal machine's wrapping force from the bottom to the top is the same, and it cannot stop during wrapping to reinforce the wrapping force. Such a function completely avoids these problems.

Saving Film Consumption

Maximum up to 380% pre-stretch rate

Minimum the value of each meter of stretch film

Standard constant releasing film

Fixed-pointed wrapping quantitative use film

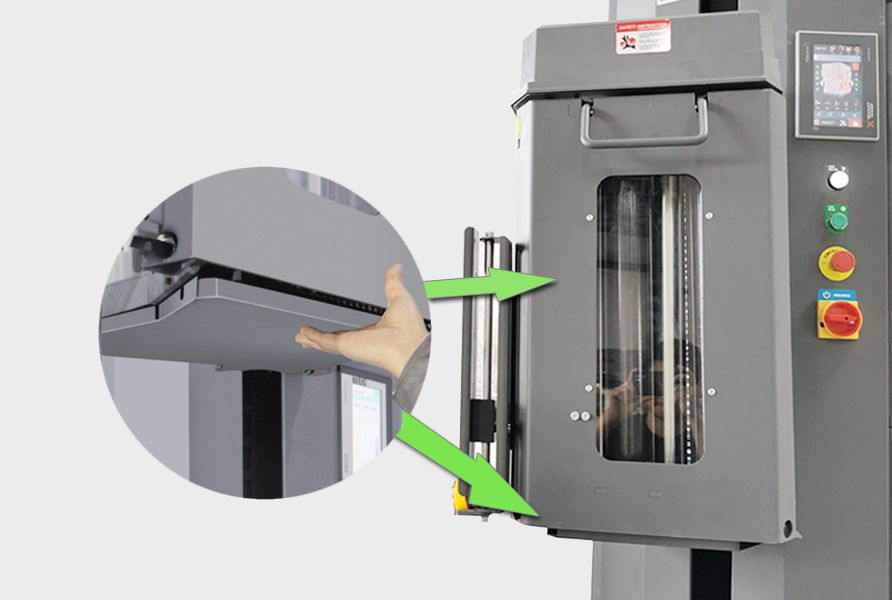

Advanced Safety Technology

1. Safety device under film carriage to protect the foot or head of the operator

2. Transparent board makes it easy to find problem without opening door

3. Up and down belt deviation and demaged alarm system. Alarming in time to avoid carriage dropping down.

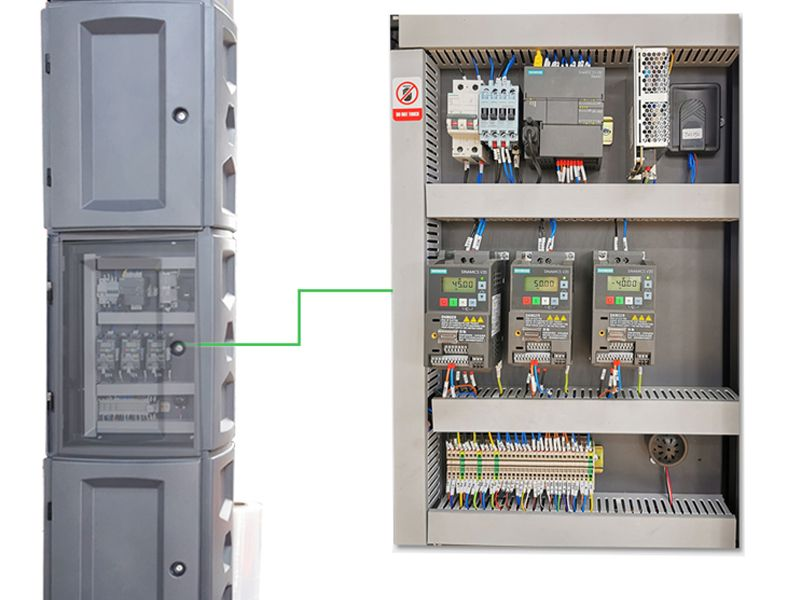

Better Components

SIEMENS PLC

SIEMENS Inverter

SICK proximity switch

AUTONICS photoelectric switch

WEIDMULLER terminal block

X-Line Inverter

OMRON 24DC supply

Intelligent Operation System

1. X100s with LED indicator on machine

Ready for work--Blue color

During working--Green color

Alarm--Red color

2. Touch screen guide the user how to operate machine.

If alarm appears, toch screen will show you how to solve problem.

Advantages of Standard Pallet Wrapper

1. High efficiency and low electricity consumption, convenient in operation.

2. The wrapping type and times can be designed on customers' requirements.

3. Photoelectric sensor test pallet height automatic

4. Auto reset of turntable

5. Pre-stretch ratio: 300%

6. Programmable control and frequency converter is available.

7. PLC control, manual optional. Wrap cycle (top, bottom, reinforcement) adjustment.Variable lift speed/ film tension control. Film up/down controls.

8. Pre-stretch pallet wrapping machine soft start and soft stop.

9. Stretch Pallet Wrapping Machine is suitable for heavy pallets, Max Wrapping Weight 2000kg. Click For More

Top Plate Optional

Motor Drive Top Pressure device

With motor drive top pressure plate, the pressure weight 35KG.

The pressure can reach from 600-2000mm, normally in market use cylinder type top pressure plate.

Such pressure just can be 1200-2000mm and must need air compressor.

| Model | Smart Wasp X100s | Spare Parts | Brand | ||||||||||

| Feature | Main Products | Inverter | SIEMENS/X-Line | ||||||||||

| Maximum wrapping speed | 15-25 loads/hour | Position sensor | SICK(Germany) | ||||||||||

| Max Wrapping Height & Weight | 2400mm / 2000KG | PLC | SIEMENS(Germany) | ||||||||||

| Turntable Speed | 0-13RPM(Adjustable) | Travel Switch | OMRON | ||||||||||

| Turntable Size | 1650mm | Motor | GPG | ||||||||||

| Turntable Drive | 0.75PH Chain Drive | Touch screen | SIEMENS 7inch | ||||||||||

| Cut Film | Automatic | Power Supplier | OMRON | ||||||||||

| Machine Size | L:2800mm W:1800mm H:2650mm | Button | Schneider | ||||||||||

| Machine Weight | 800KG | Terminal black | Weidmuller | ||||||||||

| Standard Pre-Stretch | 300% pre-stretch | AIR Breaker | SIEMENS | ||||||||||

| Film Capacity | 250mm Diameter | ||||||||||||

| Standard Film Width | 500mm | ||||||||||||

| Film Delivery System | Power Pre-Stretch | Special Process | Introduction | ||||||||||

| Packing Force | Changeable | Frame | Steel+ABS | ||||||||||

| Intelligent-Sensor | Standard | Printing | Metallic Paint | ||||||||||

| Rope Grip System | Optional | Fall-proof | Inside Safety Belt | ||||||||||

| Safety Device | CE standard | Cutting | Laser | ||||||||||

| Alarm System | Have | Turntable Roller | Double Nylon Roller | ||||||||||

| Weighing Scale | Optional | Up&Down Drive | Belt | ||||||||||

| Ramp: | Optional | Up&Down Guideway | Double Balance Device | ||||||||||