Products

MORE FEXIBLE X1000mp - put the pallet on floor directly

Don't need a ramp to load pallets

No loading weight limited

Less Installation space

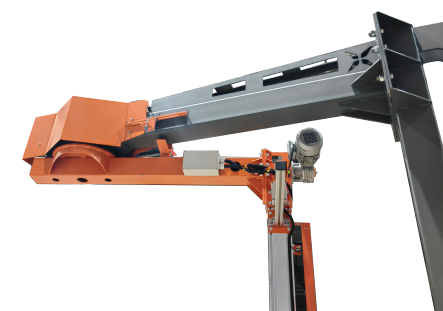

Durable Wrapping Arm

X1000mp uses Slewing bearing Drive

rotary arm works durable, quiet and no need maintenance in the future

High Level Wrapping Safety

If the arm touch anything during wrapping, whole machine will stop immediately

Intelligent operation system+PCB control system

Machine with operation guide solution, machine will teach you how to operate in the next step.

If machine have problem, there are solutions in the screen to teach you how to solve the problem at the first time.

PCB control, maintenance more easier

| Rotating Pallet Wrapping Machine Specification: | |||||||||||

| Model | Smart Wasp X1000mp | Spare Parts | Brand | ||||||||

| Maximum wrapping speed | 25-30loads/ Hour Speed | Control | PCB(SMART WASP PATENT) | ||||||||

| Max pallet size | 1.2x1.2m | Position sensor | SICK(Germany) | ||||||||

| Maximum Wrapping Height | 2000mm | Photoelectric sensor | Autonics | ||||||||

| Wrapping Speed | 3-12RPM(Adjustable) | Travel Switch | OMRON(Japan) | ||||||||

| Standard Film Width | 500mm | Rotary drive Motor | SMARTWASP Brake Motor | ||||||||

| Constant Film Delivery Force | Standard | Touch screen | X-Line(SMART WASP) | ||||||||

| Standard Pre-Stretch | 250% pre-stretch | Switch | Schneider | ||||||||

| Film Capacity | 250mm Diameter | up and down motor | SMARTWASP | ||||||||

| Film Delivery System | Motor control | ||||||||||

| up and down drive system | Belt drive | ||||||||||

| Top pressure function | optional | Special Process | Introduction | ||||||||

| Machine Size | 2.68x1.1x3.1m | Frame | Steel+Aliminum profile | ||||||||

| machine weight | 600KG | Printing | Metallic Paint | ||||||||

| Voltage | 220V/50/60HZ | Rotary Driveway | Slewing Bearing | ||||||||

How Does a Rotating Arm Stretch Wrap Machine Work?

Rotating arm stretch wrappers can wrap a high volume of loads that other machines cannot. The lack of a turntable allows you to place non-standard size and weight pallets on the floor in the wrapping zone via a forklift or pallet jack.

Once the pallet is in place, the operator then pushes a button on the control panel, and the machine immediately begins wrapping the pallet. The rotating arm then follows a preset wrap program to ensure the stability and security of the load.

Depending on the model, the machine can wrap anywhere from 25 per hour up to 300 per day.

Benefits of Rotary Arm Stretch Wrap Machines

A rotary arm stretch wrap machine allows the pallet to remain stationary during the wrap cycle. This offers several advantages:

Extremely Light Loads—On a standard turntable pallet wrapper, very light loads can fall off during the wrapping process. A rotary arm machine allows the pallet to remain securely in place, thereby preventing the load from spilling.

Extremely Heavy Loads—Turntable pallet wrappers have a max load weight. Rotary arm stretch wrappers do not have a turntable and, as such, no weight limit.

Washing Issues—Some shipping areas require regular washdowns. You can raise the rotary arm of the wrapper to avoid it getting wet during the cleaning process.

Unstable Loads—You run the risk of spilling or damaging an unbalanced load if you put it on a turntable wrapper. Rotary stretch wrap machines do not have turntables and can quickly wrap non-standard-size pallet loads.

Tall Loads—Taller loads run a risk of getting damaged when using a turntable stretch wrapper. A rotary arm stretch wrapper allows for the wrapping of much higher pallets.