Products

Automatic Cut and Clamp Film

X100a automatic cut and clamp film pallet wrapper, let workers don't need to manually cut film and put film on pallet any more, cut & clamp fim system will do it automatically .

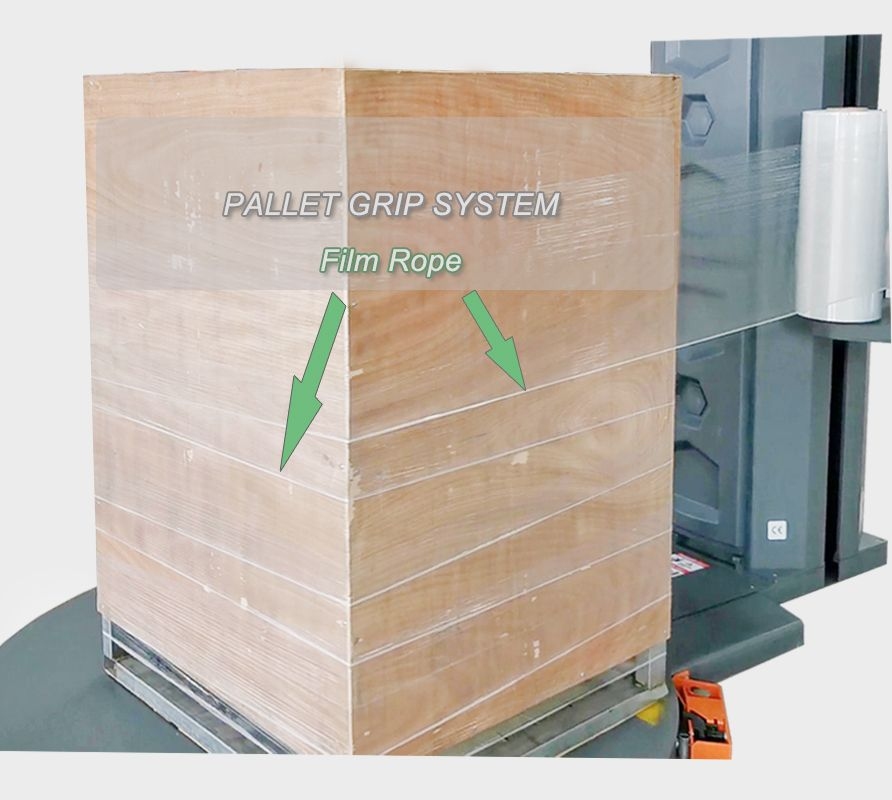

Pallet Grip System

1. Pallet grip system: film bottom narrowed to become film rope, film rope grip to pallet & products during wrapping.

2. During transporting, donn't need worry the products fall down when the pallets get violent vibration.

3. If the forklift damage the film on the bottom of pallet, the film will not break.

4. Pallet bottom grip and whole journey grip rope system can be instead of the horizontal strapping machine

Saving Film Consumption

1. Maximum up to 380% pre-stretch rate

2. Minimum the value of each meter of stretch film

3. Standard constant releasing film

4. Fixed-pointed wrapping quantitative use film

Multi-layer Function

This function can set different wrapping circles, wrapping force at any height that you want. Maximum one pallet can set 9 layers. Normal machines' wrapping force from bottom to top is the same in market, and they cannot stop or achieve reinforce wrapping function during wrapping.

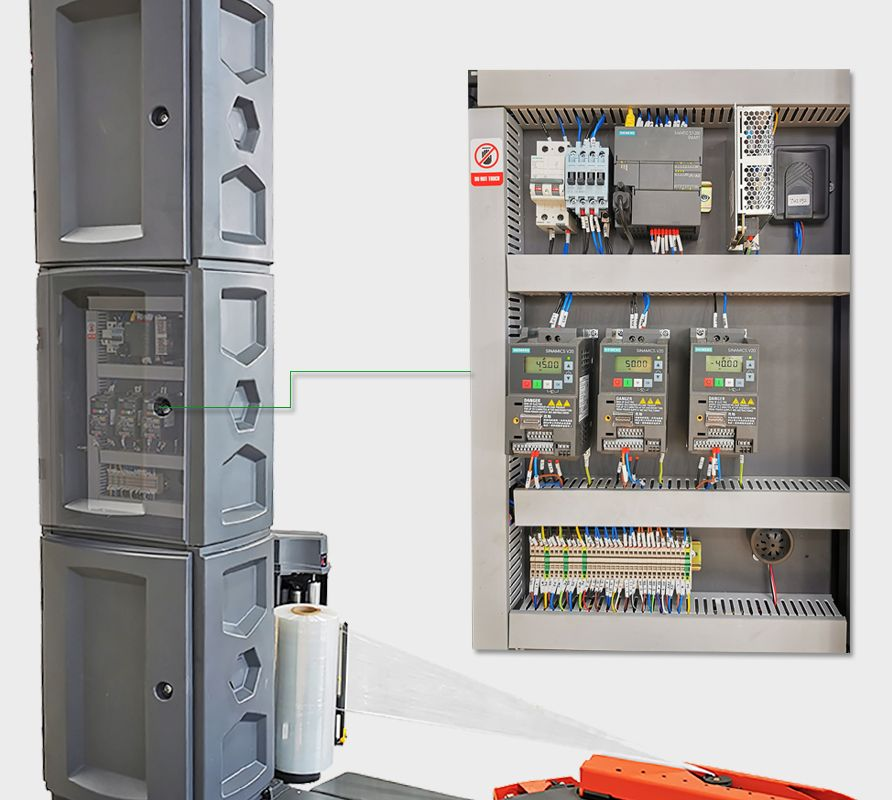

Better Components

SIEMENS PLC

SICK proximity switch

AUTONICS photoelectric switch

WEIDMULLER terminal block

SIEMENS Inverter

OMRON 24DC supply

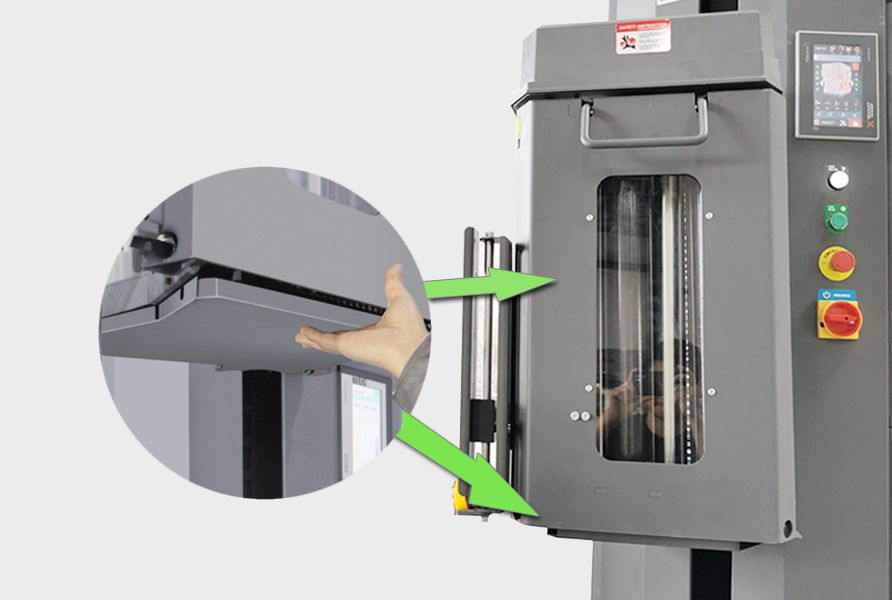

Advanced Safety Technology

1. Safety device under film carriage to protect the foot or head of the operator

2. Transparent board makes it easy to find problem without opening door

3. Up and down belt deviation and demaged alarm system. Alarming in time to avoid carriage dropping down.

Intelligent Operation Guiding System

1. Smart Wasp X100a with LED indicator on fully automatic pallet wrapping machine

Ready for work--Blue color

During working--Green color

Alarm--Red color

2. Touch screen guide the user how to operate fully automatic pallet wrapping machine.

If alarm appears, toch screen will show you how to solve problem.

Main Features of Smart Pallet Wrapping Machine

1. High efficiency and low electricity consumption, convenient in operation.

2. The wrapping type and times can be designed on customers' requirements.

3. Photoelectric sensor test pallet height automatic

4. Auto reset of the turntable, do not require an operator

5. Pre-stretch ratio: 300%

6. Programmable control and frequency converter is available.

7. PLC control ,manual optional. Wrap cycle (top, bottom, reinforcement) adjustment.

Variable lift speed/ film tension control. Film up/down controls.

8. Pallet stretch wrapping machine soft start and soft stop.

9. Suitable for heavy pallets

10. Remote control system, fully automatic cut and clamp film

11. Automatic Pallet Stretch Wrapping Machine helps you increase your production rates and reduce labor costs.

Top pressure device

Electric pressurizing system is adopted to prevent the scattering and displacement during the winding process of goods, and the pressurizing stroke is 500mm-2000mm.Compared with the traditional pneumatic pressure, the range is doubled, suitable for a wider range.

| Model | SMART WASP X100a | Spare Parts | Brand | ||||||||

| maximum wrapping speed | 20-25 loads/hour | Inverter | SIEMENS | ||||||||

| Load Size Diagonal | 1753mm | Sensor | SICK(Germany) | ||||||||

| maximum Wrapping Height | 2400mm | PLC | SIEMENS | ||||||||

| Turntable Speed | 0-12RPM(Adjustable) | Travel Switch | OMRON(Japan) | ||||||||

| Turntable Size | 1650mm | Motor | GPG(Taiwan) | ||||||||

| Turntable Drive | 1PH | Touch screen | SIEMENS/X-LINE | ||||||||

| Film Cut and Clamp | Automatic | Switch | SIEMENS | ||||||||

| Intelli-Sensor | Standard | Position switch | OMRON(Japan) | ||||||||

| Standard Film Width | 500mm | ||||||||||

| Constant Film Delivery Force | Standard | ||||||||||

| Standard Pre-Stretch | 300% pre-stretch | ||||||||||

| Wrap Force | Variable (Electric) | ||||||||||

| Film Capacity | 250mm Diametery | Special Process | Introduction | ||||||||

| Film Delivery System | Power Roller -Stretch Plus | Frame | Steel+ABS | ||||||||

| Film Rope System | Standard | Printing | Metallic Paint | ||||||||

| Integrated Scale | Optional | Fall-proof | Inside Safety Belt | ||||||||

| Machine Weight | 680KG | Cutting | Laser | ||||||||

| Machine Size | L:2800mm W:1650mm H:2745mm | Turntable Roller | Double Nylon Roller | ||||||||

| Remote Control System | Have | Up&Down Drive | Belt | ||||||||

| Voltage | 220/110V/50HZ | Up&Down Guideway | Double Balance Device | ||||||||

A pallet wrapping machine, also known as a stretch wrapper, is used to secure and stabilize palletized loads for storage or shipment. There are two main types of pallet wrapping machines: fully automatic and semi-automatic. Let's compare the two:

●Operation: A fully automatic pallet wrapping machine is designed to work without human intervention once the load is placed on the machine. It typically includes a conveyor system that automatically moves the pallets into and out of the wrapping area. The entire wrapping process, including film application, stretching, and cutting, is automated.

●Efficiency: Fully automatic machines are highly efficient, as they can wrap multiple pallets continuously without manual assistance. They are suitable for high-volume operations where a large number of pallets need to be wrapped in a short time.

●Cost: Fully automatic pallet wrapping machines are generally more expensive than semi-automatic ones due to their advanced features and automation capabilities. However, they can provide long-term cost savings by reducing labor requirements and increasing productivity.

●Complexity: These machines are more complex to operate and maintain due to their advanced automation systems. They may require skilled technicians for setup, troubleshooting, and repairs.

●Operation: A semi-automatic pallet wrapping machine requires some manual intervention to load and unload the pallets. The wrapping process, including film application and stretching, is typically performed automatically, but the operator needs to attach the film to the pallet and start the wrapping cycle.

●Flexibility: Semi-automatic machines offer more flexibility than fully automatic ones, as they allow the operator to adjust the wrapping parameters based on the specific load requirements. This can be beneficial when dealing with various load sizes, shapes, or fragile items.

●Cost: Semi-automatic machines are generally more affordable than fully automatic ones. They are suitable for operations with moderate wrapping needs that do not require continuous, high-speed wrapping.

●Ease of use: Semi-automatic machines are relatively simple to operate and require minimal training. They are suitable for businesses that have less frequent wrapping needs or variable load sizes.

The choice between a fully automatic and semi-automatic pallet wrapping machine depends on various factors such as the volume of pallets to be wrapped, desired automation level, budget, and specific requirements of the operation. High-volume operations with consistent load sizes and a need for maximum efficiency may benefit from fully automatic machines, while businesses with lower volume or variable load sizes may find semi-automatic machines more suitable.