Products

New generation of mechanical resistance film carriage

Knob with physical feedback wrapping tension, it is more convenient to adjust

Grading adjustments to make the film more uniform

6 Memory Functions + One Button Start

Six kinds of wrapping memory functions, make the parameter setting easier

One button starts, let the operation of the machine more convenient

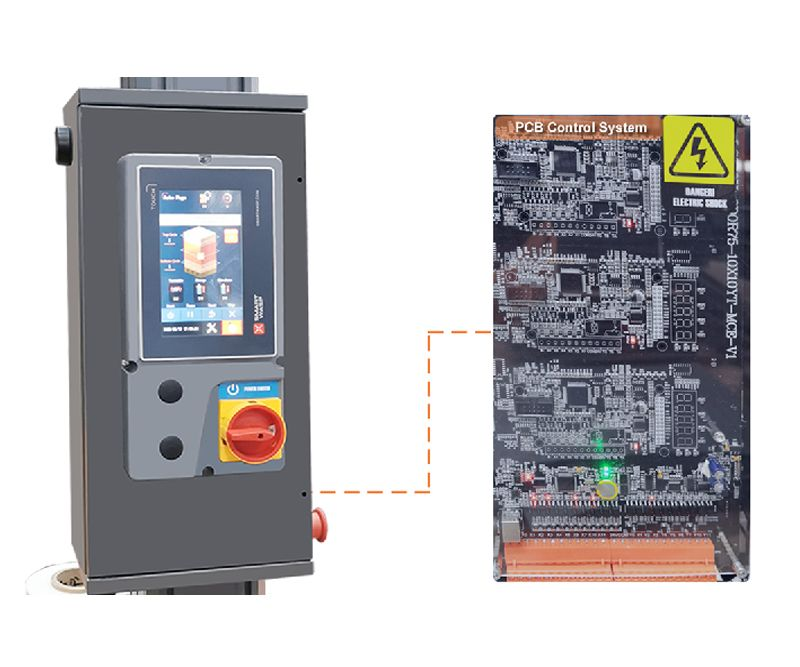

PCB control system

Four independent chips control, stronger operation and longer life

Integrated circuit system, maintenance is more convenient

All-in-one alloy Aluminum Column + Lifetime Warranty

1.4000 tons extruded column, integrally formed, solid and durable

2. Modular assembly, easy to install

3. Double chain lifting system, more safety

4. LED tri-color light

| Brand | SmartWasp | Soft start&stop | Included | ||||||||

| Model | X0ms | Intelligent Alarm | Included | ||||||||

| Load weight | 1500kg/2000kg/2500kg | Stop at original | Included | ||||||||

| Turntable speed | 3-10rpm | Turntable lock | Included | ||||||||

| Packing speed | 25-30 loads/h | Cut film | Manual | ||||||||

| Column height | 2400mm/2800mm/3200mm | Fix film on pallet | Artificial supplementary | ||||||||

| Packing height | 2000mm/2400mm/2800mm | PLC | PCB Integrated Circuit Plate | ||||||||

| Turntable size | 1500mm/1650mm/1800mm/2000mm/ 2200mm/2400mm | Inverter | |||||||||

| Turntable height | 86.7mm | Touch screen | Smart Wasp | ||||||||

| Pre-stretch rate | Mechanical Stretch | Contacts | Schneider | ||||||||

| Up&down speed | 1.5-5m/min | Button switch | Schneider | ||||||||

| Film Width | 500mm | Approaching switch | SICK | ||||||||

| Film paper Core | 76mm | Safety device | Film carriage bottom safety sensor | ||||||||

| Noise decibel | ≤75dB(A) | ||||||||||

| Working environment | Humidity: ≤90% Temperature: -10-40℃ | Pneumatic components | AirTac/Festo | ||||||||

| Motor | Smart Wasp | ||||||||||

| Machine power | 0.75KW/0.375KW/0.375KW | ||||||||||

| Voltage | 2P AC 220V 50Hz | Industrial appearance | Metal plate | ||||||||

| Machine weight | 450kg(1500mm) 530kg(1650mm) | Remote control | Optional | ||||||||

| Machine size | L2335*W1500*H2400(mm) | Certificate | CE |

A pallet wrapping machine, also known as a stretch wrapping machine, is a piece of equipment used in warehouses and distribution centers to secure and protect palletized loads. It is designed to wrap plastic film tightly around a pallet and its contents, creating a stable and secure unit for transportation or storage.

Here's how a typical pallet wrapping machine works:

●Load Placement: The pallet with the goods to be wrapped is placed onto the turntable or conveyor system of the wrapping machine. The machine should have adjustable guides or fences to ensure the pallet is properly aligned.

●Film Attachment: The operator attaches the end of a stretch film roll to the pallet, typically by manually starting the film around one of the bottom corners or using an automatic film attachment mechanism.

●Wrapping Parameters: The operator sets the wrapping parameters on the machine's control panel. These parameters may include the number of wraps, wrapping tension, film overlap, and rotational speed of the turntable (if applicable).

●Automatic Wrapping: Once the parameters are set, the machine initiates the wrapping process. The turntable rotates, or the film carriage moves up and down, while the film is automatically unwound and stretched as it is applied to the pallet.

●Film Cutting and Securing: After completing the desired number of wraps, the machine cuts the film and secures it to the pallet. This can be done using a heat-sealing mechanism or by pressing the film against itself to create a tight bond.

●Pallet Removal: Once the wrapping is finished, the operator removes the wrapped pallet from the machine, making space for the next one.

Pallet wrapping machines offer several benefits, including:

●Load Stability: Wrapping the pallet tightly helps prevent the goods from shifting or falling during transportation, reducing the risk of damage.

●Protection: The stretch film provides a barrier against dust, moisture, and other external elements that may affect the integrity or quality of the goods.

●Efficiency: Wrapping pallets manually can be time-consuming and physically demanding. Pallet wrapping machines automate the process, saving time and reducing the strain on operators.

●Cost Savings: By using the appropriate amount of film and ensuring proper tension, pallet wrapping machines can help optimize film usage, reducing material costs.

There are different types of pallet wrapping machines available, including turntable machines, rotary arm machines, and orbital machines. The choice of machine depends on factors such as the volume of pallets to be wrapped, the size and weight of the loads, and the specific requirements of the application.

It's worth noting that the specifics of pallet wrapping machines may vary depending on the manufacturer and model, so it's essential to consult the machine's user manual or contact the manufacturer for detailed instructions on operating a particular machine.