Products

Cost-saving pre-stretching film carriage

The touch screen precisely adjusts the wrapping tension

The maximum pre-stretching ratio can reach 350%, saving the amount of wrapping film

A.Rubber Coated roller+300% pre-stretch rate for the film, in market,250% stretch rate. Save 20% cost when you use our machine.Do You Understand Stretch Film?

B. Pre-stretch is normal function.

But most of machine in market, use gule stick the rubber on the roller, it's easy broken during working ,also let the film too much wrinkle. If have label on pallet, it will be difficult for scan the barcode of the label .

6 Memory Functions + One Button Start

Six kinds of wrapping memory function, make parameter setting easier

One button start, let the machine's operation more convenient

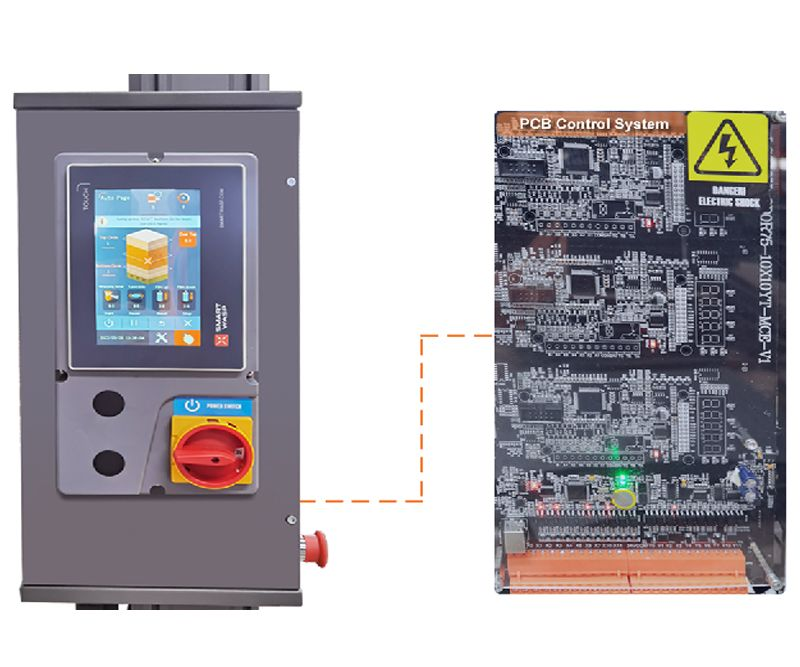

PCB control system

Four independent chips control, stronger operation and longer life

Integrated circuit system, maintenance is more convenient

All-in-one alloy Aluminum Column + Lifetime Warranty

1.4000 tons extruded column, integrally formed, solid and durable

2.Modular assembly, easy to install

3.Double chain lifting system, more safety

4.LED tri-color light

| Brand | SmartWasp | Soft start&stop | Included | ||||||||

| Model | X0ps | Intelligent Alarm | Included | ||||||||

| Load weight | 1500kg/2000kg/2500kg | Stop at original | Included | ||||||||

| Turntable speed | 3-10rpm | Turntable lock | Included | ||||||||

| Packing speed | 25-30 loads/h | Cut film | Manual | ||||||||

| Column height | 2400mm/2800mm/3200mm | Fix film on pallet | Artificial supplementary | ||||||||

| Packing height | 2000mm/2400mm/2800mm | PLC | PCB Integrated Circuit Plate | ||||||||

| Turntable size | 1500mm/1650mm/1800mm/2000mm/ 2200mm/2400mm | Inverter | |||||||||

| Turntable height | 86.7mm | Touch screen | Smart Wasp | ||||||||

| Pre-stretch rate | 100%/200%/300% | Contacts | Schneider | ||||||||

| Up&down speed | 1.5-5m/min | Button switch | Schneider | ||||||||

| Film Width | 500mm | Approaching switch | SICK | ||||||||

| Film paper Core | 76mm | Safety device | Film carriage bottom safety sensor | ||||||||

| Noise decibel | ≤75dB(A) | ||||||||||

| Working environment | Humidity: ≤90% Temperature: -10-40℃ | Pneumatic components | AirTac/Festo | ||||||||

| Motor | Smart Wasp | ||||||||||

| Machine power | 0.75KW/0.375KW/0.375KW | ||||||||||

| Voltage | 2P AC 220V 50Hz | Industrial appearance | Metal plate | ||||||||

| Machine weight | 480kg(1500mm) 550kg(1650mm) | Remote control | Optional | ||||||||

| Machine size | L2335*W1500*H2400(mm) | Certificate | CE |

Key Features:

◎Enhanced Load Security: Our machine employs pre-stretch technology to elongate the stretch film before application. This leads to superior load containment and minimized film usage, reducing costs while maximizing load stability.

◎Customizable Wrapping Settings: Tailor the wrapping process according to your load's specifications. With adjustable parameters such as stretch levels and wrap patterns, our machine ensures optimal wrapping for various load types.

◎Intuitive Controls: The user-friendly interface allows for easy operation, reducing the learning curve and streamlining your packaging process.

◎Durability and Reliability: Crafted with precision and using high-quality materials, our Pre Stretch Wrapping Machine guarantees long-term performance, even under high workloads.

◎Time Efficiency: Swiftly wrap pallets with minimal operator intervention. This boosts your operational efficiency and accelerates the overall packaging process.