Products

More stable

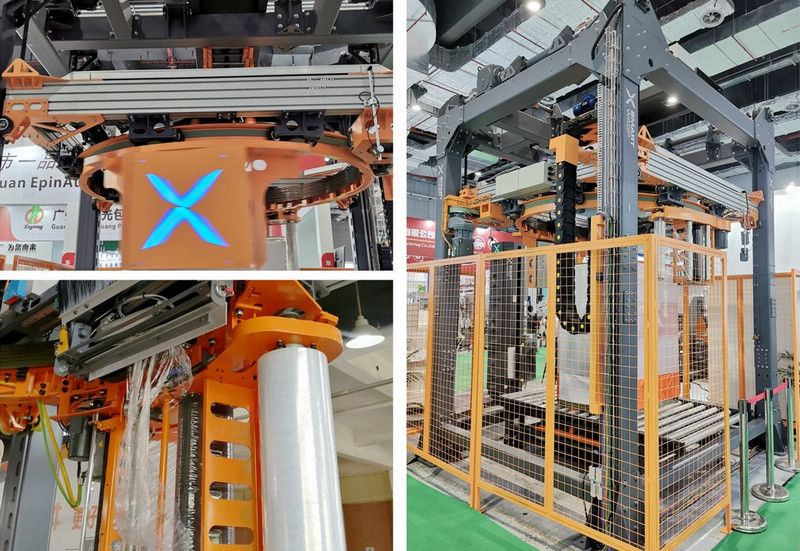

Servo drives for lifting-up, lifting-down, rotating, film feeding, more stable transmission scheme and new 4.0 software system make the whole equipment run stably.

Ring Wrapping Machines have a conveyor system that transports the pallets to the wrapping station. The wrapping station usually consists of a turntable that rotates the pallet and a wrapping arm that moves up and down to apply the stretch film. The machine can be programmed to apply the stretch film to the pallet in a specific pattern or with a particular number of wraps, ensuring that the load is secure and stable for transportation.

More energy-efficient

Compared with the Second-generation, the Third generation has more stable performance, higher speed, but the total power has lowered 26.5% (Total power of Third-generation is 11.75KW, Second-generation is 16KW) .

A high-speed fully automatic pallet wrapping machine is a piece of equipment used to wrap pallets of products securely for transportation and storage. The machine is designed to wrap the pallets automatically, which saves time and effort compared to manual wrapping.

More economical

Standard constant force film feeding system, fixed-point and quantitative wrapping system make every inch of the film get the greatest value.

Some high-speed fully automatic pallet-wrapping machines have the capacity to wrap multiple pallets simultaneously, reducing the time taken to wrap a large number of pallets. These machines may also include features such as pre-stretch film delivery systems, automatic film cutting, and film break detection to minimize downtime and increase efficiency.

Safer

Add more automatic safety protection, enhance security performance. After pressing the emergency stop button, the rotating distance reduces 75%, lifting distance reduces 90%: The pallet can be conveyed to the wrapping position, only when pallet height is smaller than max wrapping height, otherwise it can't. When the operator changes the film, the whole equipment is under automatic protection and can't be started.

A high-speed fully automatic pallet wrapping machine is an essential piece of equipment for companies that need to wrap large volumes of pallets quickly and efficiently, while also ensuring the safety and security of their products during transportation and storage.

More simple

Due to the modular design of mechanism, every part has its ID, and can be changed easily, which makes the whole components upgraded to create the new generation equipment.

Modular design of electric appliances makes system docking easier and more convenient.

Visual HMI, simple to operate, easy to understand.

Better Components

SIEMENS Servo

SICK proximity switch, photoelectric sensor

Weidmuller terminal board

SIEMENS PLC

German FESTO Air cylinder

More new technology

100% film-clamping effect

Mechanical film-cutting

Whole film roping function

| Model | Smart Wasp T1300 | Spare Parts | Brand | ||||||||

| Maximum wrapping speed | 45090loads/hour | Inverter | SIEMENS | ||||||||

| Max pallet size | 1.2x1.2m | Position sensor | SICK | ||||||||

| Maximum Wrapping Height | 2000mm | PLC | SIEMENS | ||||||||

| Ring Speed | 0-30RPM(Adjustable) | Travel Switch | OMRON | ||||||||

| Ring Size | 2200mm | Ring drive Motor | SEW | ||||||||

| Ring Drive Power | 1.5PH | Relay | OMRON | ||||||||

| Film &Clamp Cut | Automatic (Heat type) | Touch screen | SIEMENS | ||||||||

| Max Load Weight | 2000KG | Switch | Schneider | ||||||||

| Standard Film Width | 500mm | Cylinder | FESTO & AIRTAC | ||||||||

| Constant Film Delivery Force | Standard | Up and down motor | CPG | ||||||||

| Standard Pre-Stretch | 250% | Film carriage motor | SIEMENS servo motor | ||||||||

| conveyor system | Stainless Steel 201 diameter: 76mm | ||||||||||

| Film Capacity | Diameter: 250mm | Special Process | Introduction | ||||||||

| Film Delivery System | Servo motor control | Frame | Steel | ||||||||

| Up and down drive system | Belt drive | Printing | Metallic Paint | ||||||||

| Top pressure function | Optional | Fall-proof | Anti drop system | ||||||||

| Lifting up conveyor | Optional | Cutting | Laser | ||||||||

| Top sheet dispensor | Optional | ||||||||||

| Paper corner fixer | Optional | ||||||||||

| Machine Size | 3.2x3x4m | ||||||||||

| Machine weight | 4000KG | ||||||||||

| Voltage | 380V/60HZ | ||||||||||