Products

E type turntable

Smart Wasp X100a-MT Turntable Fully Automatic Pallet Wrapping Machine is equipped with an E-type turntable, designed to simplify the loading process. The E-type turntable allows pallets to be easily loaded by a pallet jack, eliminating the need for additional lifting equipment and reducing setup time.

Automatic cut and clamp film

With the X100a-MT's automatic film cut and clamp feature, manual handling is no longer necessary. This Turntable Fully Automatic Pallet Wrapping Machine automates the cutting and clamping process, freeing workers from having to manually secure film on each pallet. This functionality enhances efficiency and reduces the risk of injury, making it an ideal choice for high-volume operations.

Remote control system

The X100a-MT Pallet Wrapping Machine also includes a remote control system, allowing operators to initiate the wrapping process with the press of a button. Forklift operators can stay seated, load the pallet onto the turntable, and activate the Turntable Fully Automatic Pallet Wrapping Machine remotely. This feature increases productivity by reducing the time operators spend away from their primary tasks.

LCD touch operating system

SMART WASP pallet wrapping machine uses intelligent IoT touch screen, the reaction of the touch screen and function are perfect. The touch screen can set the "turntable speed, up& down speed and film carriage speed directly" and we also prepare for our customer 6 wrapping models for the pallet. Most of the customers have different pallets to wrap, so the different pallets need different wrapping speeds, and wrapping forces, the customer just needs to set the 6 models one time, then just choose the right model for the pallet, do not need to adjust the parameter each time anymore.

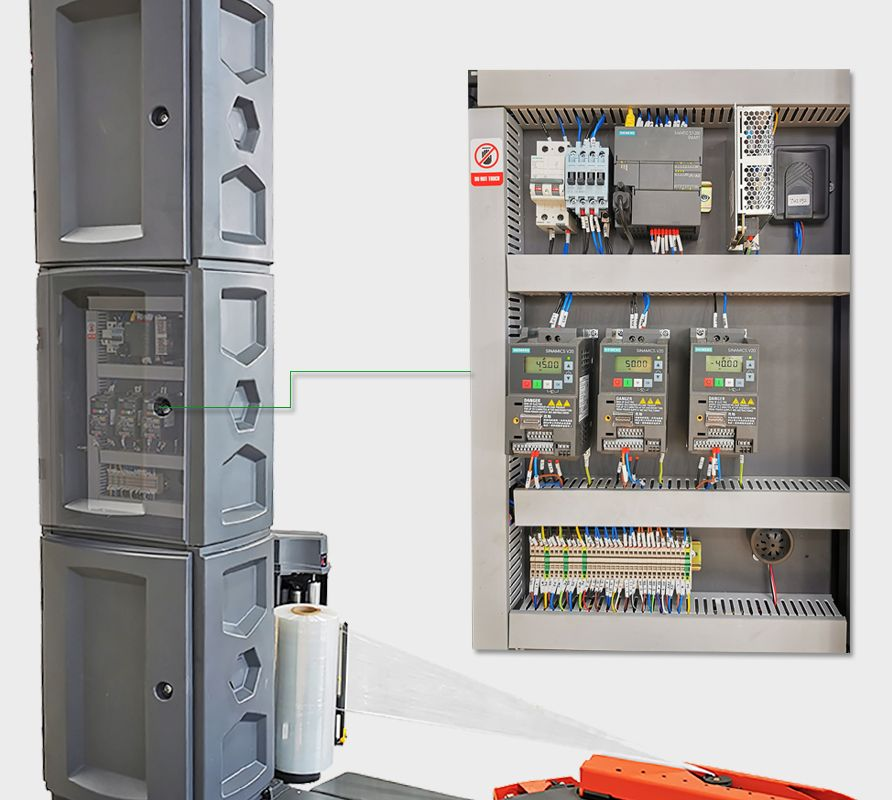

We use Good Brand Components

To ensure long-lasting performance, the Turntable Fully Automatic Pallet Wrapping Machine is built with components from renowned brands. Using high-quality electrical parts minimizes the risk of breakdowns and ensures seamless operation over time. Each part is selected to maximize machine longevity, giving users a durable and reliable Standard Pallet Stretch Wrapper for years to come.

SIEMENS Programmable Logic Controller

SICK Switch

AUTONICS Photoelectric Switch

WEIDMULLER Terminal Block

SIEMENS Inverter

OMRON Supply

Alarm system

Safety is a priority in the design of the Turntable Fully Automatic Pallet Wrapping Machine. The X100a-MT is equipped with an automatic alarm system that activates during emergencies, promptly notifying operators to any issues. This feature ensures a safe working environment while preventing potential damage to the machine or product.

Main Features

High Efficiency and Low Power Consumption: The X100a-MT is designed to maximize energy efficiency while maintaining high performance, making it a cost-effective addition to your production line.

Customizable Wrapping Options: Tailor the wrapping type and frequency according to specific needs, whether for added reinforcement or standard wrapping cycles.

Automatic Pallet Height Detection: A photoelectric sensor automatically detects the pallet height, ensuring precision in the wrapping process.

Automatic Reset of Turntable: After each wrapping cycle, the turntable automatically resets, readying the machine for the next pallet.

Pre-Stretch Ratio up to 300%: This high pre-stretch capability helps minimize film use, saving on material costs.

Programmable Control Options: Equipped with a PLC control and frequency converter, the machine offers flexible control over wrap cycles, film tension, and lift speed.

Soft Start and Stop Functions: Ensuring smooth operation, this feature is essential for wrapping lighter pallets securely.

Remote-Control System: For ultimate convenience, the Turntable Fully Automatic Pallet Wrapping Machine is fully automated and can be operated via remote control, allowing forklift operators to control the wrapping cycle from their seats.

| Model | Smart Wasp X100a-MT | Spare Parts | Brand | ||||||||||

| Feature | E Shape Turntable | Inverter | SIEMENS | ||||||||||

| Maximum wrapping speed | 15-25 loads/hour | Photoelectric sensor | SICK(Germany) | ||||||||||

| Max Wrapping Height & Weight | 2400mm / 800KG | PLC | SIEMENS(Germany) | ||||||||||

| Turntable Speed | 0-12RPM(Adjustable) | Travel Switch | OMRON(Japan) | ||||||||||

| Turntable Size | 1650mm | Motor | GPG(Taiwan) | ||||||||||

| Turntable Drive | 0.75PH Wheel Drive | Relay | OMRON(Japan) | ||||||||||

| Cut And Clamp Film | Automatic | Reducer | GPG | ||||||||||

| Machine Size | L:2700mm W:1650mm H:2675mm | Touch screen | SIEMENS 7inch | ||||||||||

| Machine Weight | 900KG | Position switch | OMRON(Japan) | ||||||||||

| Standard Pre-Stretch | 300% pre-stretch | ||||||||||||

| Film Capacity | 250mm Diameter | ||||||||||||

| Standard Film Width | 500mm | ||||||||||||

| Film Delivery System | Power Pre -Stretch | Special Process | Introduction | ||||||||||

| Packing Force | Changeable | Frame | Steel+ABS | ||||||||||

| pre-stretch Rate | 300% | Printing | Metallic Paint | ||||||||||

| Voltage | 220V/110V/50HZ | Fall-proof | Inside Safety Belt | ||||||||||

| Safety Device | Have | Cutting | Laser | ||||||||||

| Alarm System | Have | Turntable Roller | Double Nylon Roller | ||||||||||

| Weighing Scale | Not available | Up&Down Drive | Belt | ||||||||||

| Pallet Jack For Size | 1200*750mm | Up&Down Guideway | Double Balance Device | ||||||||||

Product Application

1. The E Type Turntable Fully Automatic Pallet Wrapping Machine uses LLDPE stretch film as the main packing material to wrap the bulk cargo stacked on the pallet

2. Film provides extra support during transportation and storage to protect them from dust, moisture or damage

3. The E Type Turntable Fully Automatic Pallet Wrapping Machine has been widely used in industries such as glassware, tools, electric & electronic, paper, pottery, food & beverage, etc.