Support

Table of Contents

1. Introduction

2. Labor Cost Overview

3. Automatic Pallet Wrappers

4. Semi-Automatic Pallet Wrappers

5. Labor Cost Comparison

6. Featured Snippet Claim

7. Case Study: Labor Cost Analysis

8. Conclusion

1. Introduction

Choosing between Automatic Pallet Wrappers and Semi-Automatic Pallet Wrappers can significantly impact operational efficiency and labor costs. Automatic wrappers automate the wrapping process, while semi-automatic models require some manual intervention, leading to differences in labor requirements and costs. This article explores the implications of these differences in the context of labor cost analysis.

2. Labor Cost Overview

Understanding labor costs is crucial for manufacturers who rely on pallet wrapping solutions. Factors influencing labor costs include:

Number of workers required

Time spent per task

Training and efficiency levels

3. Automatic Pallet Wrappers

Automatic pallet wrappers reduce labor costs by minimizing the number of operators needed. Here's how they compare:

Integrated systems, which operate independently.

Consistent results with less variability.

Higher production speeds leading to increased throughput.

3.1 Benefits of Automatic Wrappers

Consider the following benefits:

Fewer employee hours required.

Lower training needs for operators.

Reduced risk of workplace accidents.

4. Semi-Automatic Pallet Wrappers

Semi-automatic pallet wrappers offer a balance between manual control and automation. Here's what to consider:

They require at least one operator for loading.

Flexibility in wrapping different products.

Lower upfront costs than fully automatic models.

4.1 Benefits of Semi-Automatic Wrappers

Cost-effective for small volumes.

Manual control allows fine-tuning.

Ease of maintenance and repair.

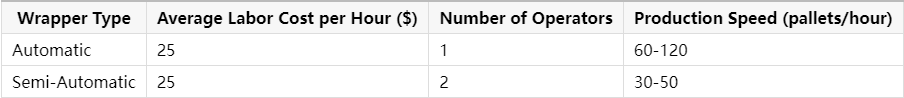

5. Labor Cost Comparison

5.1 Key Insights

While automatic wrappers represent a higher initial investment, their labor savings can quickly offset costs. In contrast, semi-automatic models may require higher ongoing labor costs due to the necessity of more operators.

6. Featured Snippet Claim

To analyze which pallet wrapper is more cost-effective, consider:

Initial investment versus long-term labor savings.

Operating costs associated with labor.

Production efficiency and output quality.

7. Case Study: Labor Cost Analysis

In a manufacturing case study conducted in 2023:

One of our customers implemented automatic pallet wrappers, reducing labor costs by 30% over six months compared to their previously used semi-automatic wrappers.

8. Conclusion

The choice between automatic and semi-automatic pallet wrappers depends on specific operational needs. For large-scale operations, the investment in automatic wrappers may yield significant labor savings, while smaller businesses may find semi-automatic options more suitable. Assess your production needs, labor costs, and budget to make an informed decision.